Submerged bearings design,development nad producing;dDesign value of Turbine blade in the development ofspecial software;Development and test of large-sized pump and fan model;

Submerged Bearing

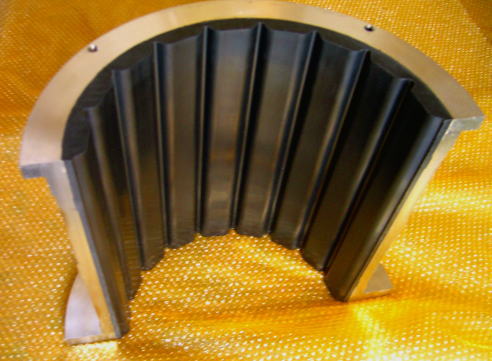

Rubber bearing

「Rubber bearing」

Rubber bearing is mainly used in axial flow

pump and mixed-flow pump in water. It is quite capable for atomic power station

and circulating water pump, washer pump, cooling water pump, seawater pump and

draining pump of energy power station. On the other hand, due to the oil

lubrication way got a high regard again, rubber bearing is still widely used in

stern bearing, rudderpost bearing and main shaft bearing of dredge.

Main features:

1、Less power loss

Generally, there

is a few friction between moisten rubber and mental. The rubber developed by

our company makes the friction less. The following is a comparison about friction

factor.

The frictional pair friction factor

Rubber to metal (moisten) 0.001~0.005

Rubber to metal (dry) 0.5

Cast iron to cast iron (less oil) 0.15

Cast iron to bronze (dry) 0.22

Cast iron to lignum vitae (less oil) 0.19

Wrought iron to lignum vitae (less oil) 0.08

Roller bearing

0.014

Ball bearing

0.001

2、Less friction

Rubber bearing’s

abrasion-resisting quality is better than lignum vitae (wooden blocks and

wooden bearings’ materials), The lignum vitae has to be replaced in a few

months use, as a rubber bearings can last more than 4 years.

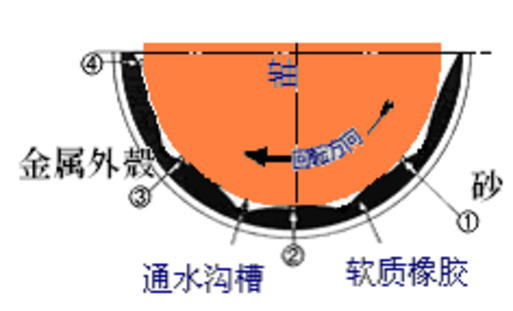

3、Less harm on shaft and shaft sleeve

Even if there is

sand or small stone put into shaft and rubber bearing, it can be ruled out

following the rotation of bearings for its lubricant water. In order to fully

understand its feature, our company made a special study on the rubber.

4、Anti-phone and shock absorption

4、Anti-phone and shock absorption

Because the

friction is rather small between rubber bearing and shaft, the rubber’s anti-phone

and shock absorption effect is clearly.

5、No public pollution

For the

lubrication materials is water instead of oil, public pollution will not

happen.

6、Taglia di produzione

The maximum diameter is 850 millimeters. If you want

specifications and specific design information of product, please contact with

us.

Submerged Bearing

KUNITOMI INDUSTRY CO., LTD.

〒410-0875

10-10 Imazawa Numatsu

Shizuoka-Ken Japan

TEL 0081-55-968-6322

FAX 0081-55-968-6325

E-mail:kunitomi@ktt-tec.co.jp